Table of Contents

eCommerce and retail businesses often grapple with the issue of stockouts and overstocking, both come with their own set of challenges. Stockouts can result in missed sales opportunities and unhappy customers, whereas overstocking can tie up capital and boost profits.

In these cases, the role of effective inventory management comes up. Modern inventory systems offer a lifeline, enabling businesses to fine-tune their stock levels, enhance operational efficiency, and minimise excess.

Did you know?

- The global inventory management software market was valued at $2,783.53 million in 2021, and it is projected to grow at a CAGR of 9.94%, reaching $4,916.27 million by 2027.

- Addressing overstocking and understocking can lead to a 10% reduction in business inventory costs.

- 72% of retailers plan to review their supply chain operations by implementing real-time visibility through automation and analytics.

- Approximately 46% of small-to-medium businesses either do not track inventory or rely on manual tracking methods.

What is an inventory software: custom inventory system vs. ready-made solution

Inventory management software is a digital system designed to monitor stock quantities, manage orders, track sales, and facilitate deliveries. In the manufacturing sector, it enables the generation of work orders, bills of materials, and various production-related documents.

This software helps businesses prevent excess inventory and shortages by replacing traditional record-keeping methods, like physical documents and spreadsheets, with streamlined, digital data organisation.

When planning inventory tracking software development, you can choose between two approaches.

- Off-the-shelf solutions

- Custom development from scratch

Each of them has its advantages. Let’s take a look at the key nuances.

Ready-made inventory software

Ready-made inventory management systems are software solutions designed to serve a wide range of businesses. Although these systems are helpful for their availability and swift setup, they might not completely meet the specific business needs. However, existing systems remain a practical option for businesses eager to implement inventory software immediately.

Custom inventory management software development

Developing custom inventory solution is about creating a system smoothly aligned with the unique needs of your business. This bespoke software smoothly integrates with a company’s warehouse operations, enabling precise tracking, management, and optimisation of inventory levels, purchasing, sales, and storage activities.

Here are the key reasons why custom inventory software development more effectively addresses business requirements.

Real-time inventory insights

Such software facilitates the instant monitoring of stock quantities, whereabouts, and movements. This capability ensures precise inventory oversight across various storage locations, diminishing the risks of running into stockouts, surplus inventory, or misplaced items.

Achieving this degree of oversight not only improves customer satisfaction but also boosts the efficiency of business operations.

Demand forecasting

The development of inventory software includes the integration of data analytics for demand forecasting. By examining historical sales data, businesses can make data-driven decisions about restocking, thereby reducing instances of overstock and streamlining inventory levels.

Order and purchase management

Inventory management systems help to automate the purchase order management process. When stock quantities hit specific set points, the software can autonomously initiate purchase orders to guarantee prompt restocking. Consequently, your procurement process will be streamlined and avert disruptions in the supply chain.

Reduced costs and errors

An inventory management system significantly reduces reliance on manual data entry and spreadsheet usage. Through automation, it eliminates human error like inaccuracies in order amounts or product misplacements. Moreover, optimising stock levels helps lower the financial obligations tied to surplus inventory.

Customisation to your workflow

Every business has its workflows, processes, and strategies for managing inventory. Custom inventory management software aligns flawlessly with your current operations, ensuring the solution is tailor-made for your business. This personalised approach boosts operational efficiency by eliminating the need for altering processes or investing in extensive staff training.

Scalability and flexibility

Your inventory management demands will evolve as your business expands. Pre-packaged solutions need help to keep up at scale. In contrast, custom software development offers scalability to adapt to changing needs, ensuring your inventory management solution can grow with your business while maintaining peak performance.

Data security and compliance

Businesses adhere to strict data security and compliance standards in specific industries. Custom inventory management software development ensures that your system is built with these considerations, safeguarding sensitive information, and ensuring that your operations comply with relevant industry regulations.

Long-term cost-effectiveness

While the initial outlay for custom inventory management software might seem substantial, the long-term financial benefits are persuasive. Custom solutions do away with the recurrent licensing fees associated with off-the-shelf software.

Moreover, they minimise the likelihood of operational disruptions and inefficiencies often encountered with generic systems, further contributing to long-term savings.

What are the technical requirements for a modern eCommerce inventory management system?

When choosing or designing inventory management solutions, companies face some challenges, many of which have been touched upon but represent just the beginning of what needs to be considered. The key requirements include the following.

High availability

In a nutshell, the risk of system downtime can result in large financial losses for a company. Thus, inventory management solutions must boast high availability, ensuring they always remain operational. Such systems must be reliable and resilient, ensuring data integrity and preventing information loss.

In the quest for an effective solution, eCommerce companies should prioritise inventory features that address not only the immediate challenges but also the scalability and adaptability demand of a global marketplace.

Global consistency

An inventory management tool should reliably track and report accurate stock levels, making this information available to all necessary applications in real-time. It involves direct access or mechanisms like change feeds to ensure data consistency across all use points.

Flexible scaling

The infrastructure of any retail backend, especially inventory management, must be agile enough to scale up to accommodate surges in demand during peak sales periods and scale down to conserve resources during slower times. This flexibility is essential for managing costs effectively while ensuring the system remains responsive to varying loads.

Geographical scalability

The ability to geolocate data not only enhances the customer experience by providing more relevant information and services but may also be necessary to comply with specific regional regulations.

User-friendliness

While managing inventory is inherently complex, simplifying the system’s interface and opting for managed services reduces the burden on internal resources. A relatively simple system interface decreases the time and expense involved in training and system management, making it a more cost-effective solution in the long run.

What you can improve with eCommerce Inventory Management Software

Inventory management software solution has shaken up the way businesses handle stock, addressing numerous challenges and bringing many benefits. Here are some of the top advantages of implementing such systems.

Sales

Using various inventory management technologies, these software systems help to monitor and manage products availability and provide low stock alerts. This feature ensures businesses can proactively replenish inventory, avoiding stockouts and consistently meeting customer demand.

Storage management

Managing inventory across multiple warehouses in different locations was a significant challenge some time ago, often leading to inefficiencies and errors. Cloud-based inventory management software offers a centralised overview of stock levels and locations. This feature enables accurate tracking and distribution of items, ensuring that customers receive the right products promptly, regardless of where the stock is held.

Planning and forecasting

An automated system for tracking inventory significantly facilitates forecasting future demand for products, enabling businesses to make informed decisions just in time. If a surge in demand for a specific product is anticipated, companies can ensure they have adequate stock on hand to meet this increase—and the reverse is true for expected drops in demand.

Integrating analytical tools with an inventory control system is important for gauging market trends and consumer expectations facilitating strategic stock management.

Latest tech developments in eCommerce inventory management

As inventory management software continues to shake up the way companies handle their logistics and maintain precise records of their stock movements, technological innovations are showing no signs of slowing down.

These advancements focus on improving periodic and perpetual inventory systems, aiming for a frictionless user experience. Among the key technological advancements reshaping inventory management capabilities are.

Machine Learning

Traditional inventory management often implies repetitive tasks that are time-consuming and prone to errors, impacting the efficiency of the entire process. Incorporating machine learning into automated inventory tracking systems emerges as a game-changing solution.

ML enables voice and image search features, allowing clients to locate items quickly. It also helps predict future inventory needs and improve stock level optimisation.

Furthermore, machine learning-powered inventory functions can promptly notify vendors about any disruptions in the supply chain, ensuring a more resilient and responsive logistics operation.

Blockchain

For those keenly following technological advancements, blockchain guarantees data integrity. Once information is recorded on the blockchain, it becomes immutable and cannot be altered by any single vendor or stakeholder.

This feature significantly improves the reliability of automated inventory tracking systems by ensuring that all data must be accurate and unanimously approved by all involved parties.

Blockchain technology facilitates collaboration among retail partners, suppliers, manufacturers, and warehouses, allowing them to share and access real-time information with no hassle.

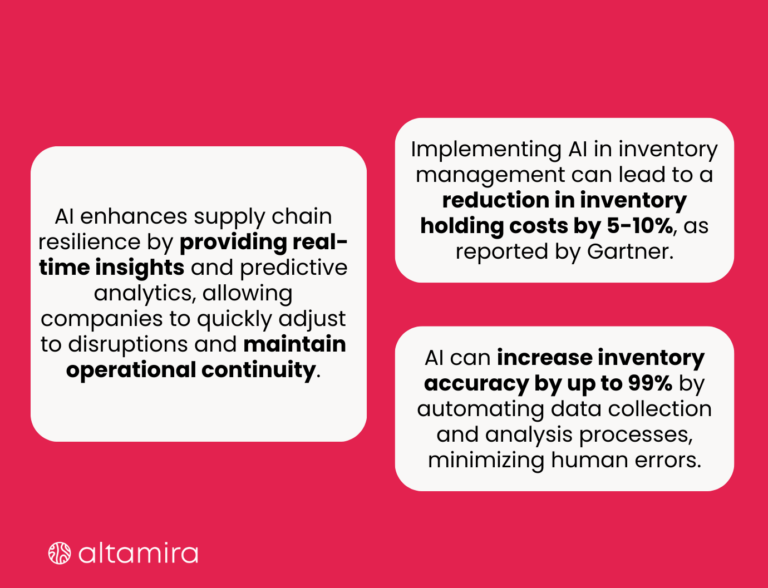

Artificial Intelligence

Forecasting future product demand and making informed decisions based on these predictions can significantly impact sales, a goal every vendor strives for. Artificial intelligence is at the forefront of making this possible by analysing historical data to provide estimates of future market demand for products.

This predictive capability helps businesses plan their inventory levels more effectively, ensuring they are well-prepared to meet consumer demand without the risk of stockouts. AI’s ability to analyse vast amounts of data and identify patterns enables more accurate forecasting, optimising inventory management, and boosting sales figures.

Challenges we solve with our eCommerce inventory management

eCommerce inventory represents a unique set of challenges that, if not addressed proactively, can impede a business’s growth, and negatively impact customer satisfaction and retention.

Recognizing and tackling these issues head-on can potentially streamline operational efficiency and profitability. Here’s a closer look at some of the most common inventory management challenges faced by e-commerce businesses.

Lack of insights

The absence of complex data insights into inventory can hinder effective management. Access to detailed inventory data is the first step to qualitative analytics that can identify areas for improvement, helping businesses increase engagement and revenue. Key insights include the assessment of inventory accuracy, order returns reduction, and supply chain process optimisation. This information can improve forecasting, meet customer demands more effectively, and identify weak points in existing processes.

Overstocking

Misjudging customer needs can lead to excess supply, resulting in higher estimated costs and the risk of deadstock—items that can’t be sold due to overabundance or changing trends. While having a full-stock inventory has advantages, especially before a busy season, it also comes up with challenges, such as increased costs and the potential for unsellable stock.

Overselling

Failing to monitor inventory accurately can lead to overselling, where customers can purchase items that are no longer in stock. This causes significant customer service issues, eroding trust and potentially harming the business’s reputation. Offering real-time stock status online helps mitigate this risk by allowing customers to see what’s available.

Lack of visibility

Expanding multiple sales channels and warehousing can lead to visibility issues, making it challenging to monitor sales, orders, and inventory levels across different platforms and locations. Implementing an Enterprise Resource Planning (ERP) system with an advanced inventory management module can simplify tracking and ensure consistency across all channels and warehouses, supporting business growth and maintaining a uniform brand experience.

Manual management

Reliance on manual inventory management methods becomes increasingly untenable as a business grows. Scaling up involves expanding multiple sales channels, partnering with more manufacturers and distributors, and possibly using multiple warehouses. Manual methods, such as offline spreadsheets or disparate tools, can lead to errors and inefficiencies. Transitioning to automated and integrated inventory management solutions is key to supporting long-term growth and reducing the risk of errors.

Addressing these challenges requires careful planning and adopting scalable inventory management practices and technologies that can support the evolving needs of an eCommerce business.

Conclusion

The development of inventory management software has addressed one of the most significant challenges faced by the business world: efficient planning. This type of software greatly helps companies in monitoring, optimising, and overseeing their products and raw materials, thereby streamlining the delivery process to customers.

Given the widespread adoption and success of these systems, today, companies that have yet to integrate inventory management software into their operations consider doing so. This move promises to enhance operational efficiency and position businesses to better meet customer demands and expectations.

At Altamira, we help eCommerce startups, medium-sized businesses, and enterprises sustain and grow in the market through qualitative software able to fine-fune internal processes, and contribute to customer satisfaction and retention. With the help of custom inventory management software, you can facilitate every process related to your business planning and order management, offering your customers more valuable features.

Contact us to discuss your project!