Table of Contents

It’s not a secret that every logistics, retail, and manufacturing business deals with a huge number of products. And the success of any company from these sectors directly depends on its ability to manage all the inventories effectively. This means that products need to be properly accepted to a warehouse, assigned with a relevant status, tracked, and then written off.

On top of that, all the mentioned tasks have to be done quickly and accurately since slowness and mistakes are not the things that create a competitive advantage in today’s fast-paced world.

In this blog post, we will explain all the ins and outs of inventory management system (IMS) and how this software can help you gain full control over the goods you store or sell. We will also outline the main benefits a company gets when it opts for the development of a custom inventory solution.

What is an inventory management system (IMS)?

Simply put, an inventory management system software is aimed at automating the core processes related to tracking of goods in stock from the moment they appeared in a warehouse or other business premises and to the moment they leave it.

Historically, a single goal of inventory systems, which mostly looked like simple spreadsheets, was to organize inventory data and keep it in order. But new technologies opened a door to many more opportunities. So modern inventory software is not limited just to recording information about products available for sale. Nowadays, it is much more focused on data-driven management, cooperation, and efficiency.

An inventory management system may be built either as a standalone solution or as a part of another more comprehensive logistics system, for instance, a warehouse management system or supply chain management (SCM) software. Both options have their pros and cons so the choice should be made considering the business needs of a particular organization.

Types of software for inventory management

Inventory solutions are the category of management software that can be used by a wide range of businesses, from logistics providers and freight forwarders to online merchants. Since operations and activities of every such organization have certain specifics, different companies need a different type of inventory management systems. The main types include the following:

Warehouse inventory management system (WIMS)

As the name suggests, warehouse inventory management software is used by logistics companies to manage warehouse operations. As a warehouse only provides storage services and doesn’t own any inventories itself, the main purpose of WIMS is to ensure that all items can be found quickly.

Manufacturing inventory management system (MIMS)

Manufacturers need an inventory system to store raw materials and finished products. Hence, the primary task of any MIMS is to help factory managers maintain balanced levels of both types of inventories so that the production process is smooth and continuous.

Retail inventory management system (RIMS)

RIMS is one of the most useful software solutions for every retail company. This is because it helps merchants build and maintain an effective supply chain that is a foundation of any business related to selling goods. The key focus of retail inventory management systems is on planning and prevention of product stockout or overstock.

Key features of inventory management software

The core component of most inventory solutions is, of course, an inventory database. Typically, such a database stores the records about product names, stock-keeping units (SKU), and quantity of every item. Depending on the type of solution, it may also contain other information such as suppliers, location, purchases, clients, materials, etc.

Yet, although the inventory database is a common element for most inventory software, the exact functionality of every custom solution depends on the specific problems a particular business needs to solve.

Among others, it may cover such features of inventory management software as:

Inventory control

Inventory control allows a system to notify managers when the number of certain items falls under or exceeds a predefined threshold. Once it happens, the company’s officers receive an alert about the need to reorder additional items or make other business decisions. This feature is especially useful for retailers and manufacturers since it helps to avoid running out of certain products or materials as well as identify when the company puts too much money in inventories.

Barcode scanning

Barcode scanning is a standard feature of warehouse inventory management systems. It automates basic processes related to incoming shipments and outcoming orders such as picking, packing, and sending out of products. On top of that, barcodes allow warehouse employees to quickly look up information about a product as well as track its movements and location.

Planning and forecasting

This analytic feature of inventory solutions helps business owners and top managers run their businesses more wisely. Specifically, it allows company officers to forecast demand for certain products and order / produce the required number of items in advance. In addition, planning and forecasting feature may show how many days are left before the complete stockout.

It’s worth mentioning that forecasting tools embedded in inventory management solutions may have a different level of technical complexity. Again, everything depends on the company’s requirements and budget for software development. For instance, the most advanced inventory systems may use machine learning algorithms to anticipate demand and customers’ behavior even more accurately.

Reporting

Inventory management solutions make reporting an easy task. Basically, you just need to choose categories of information you require and the relevant report will be ready in one click. Another benefit is that reports generated by an inventory management system may be created in different formats.

For instance, if you need to show this information to stakeholders, it may look like a graph since visualization helps to perceive critical information faster. On the other hand, if you want to focus on numbers in order to make a strategic decision regarding a specific product, a report may be generated in the format of a table containing all the data about such a product.

Planning and forecasting

This analytic feature of inventory solutions helps business owners and top managers run their businesses more wisely. Specifically, it allows company officers to forecast demand for certain products and order / produce the required number of items in advance. In addition, planning and forecasting feature may show how many days are left before the complete stockout.

It’s worth mentioning that forecasting tools embedded in inventory management solutions may have a different level of technical complexity. Again, everything depends on the company’s requirements and budget for software development. For instance, the most advanced inventory systems may use machine learning algorithms to anticipate demand and customers’ behavior even more accurately.

Integration with a third-party accounting system

An inventory management system may contain its own accounting tools but it’s quite a rare case. Usually, when a company decides to develop inventory software, it already uses a third-party accounting solution that covers not only inventories but also other assets such as office premises, equipment, etc. For this reason, an inventory management system should be able to “communicate” with such a solution. Otherwise, many discrepancies may occur between two systems that potentially might lead to rather negative consequences as well as significant financial losses.

How a company benefits from the inventory system?

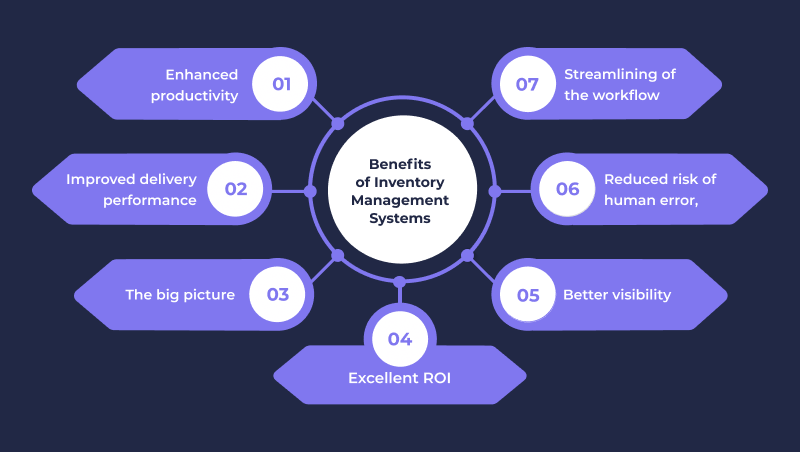

If an organization deals with a great number of goods, building a custom inventory management solution may benefit it in numerous ways

Streamlining of the workflow

Basically, any automation does that so it’s the most obvious advantage. Inventory software helps to perform routine tasks faster and more efficiently. It also helps the company’s officers identify and eliminate bottlenecks which slow down business operations.

Reduced risk of human error

Stock levels are continuously going up and down so it is almost impossible to keep track of them manually. The inventory management solution solves this problem. Since most processes are completed automatically, there is no risk of human error.

Better visibility of inventories

This is probably the most important benefit for top managers since better visibility gives more control over inventories. It is no longer a guessing game. With all the data available in a few clicks, the company’s officers can make more informed decisions as well as avoid overselling and stockout.

Enhanced productivity

An inventory management system makes the life of employees easier. First of all, it shortens the list of day-to-day tasks an employee should perform. Secondly, the integration of new employees into the working process becomes faster. All these things have a positive impact on overall staff productivity.

Improved delivery performance

Ever heard that nowadays time is money? With inventory software and its real-time updates on products in stock, you can maintain a smooth and continuous flow of goods from you to your customers. Besides being beneficial for your business operations, improved delivery performance will also help you achieve higher customer satisfaction.

The big picture

The inventory management solution allows for advanced analytics of your supply chain. This is because it lets you take a bird’s eye view on your business and, as a result, facilitates better strategic decision-making.

Excellent ROI

Yes, development of a custom inventory system might seem costly but, as we see from the practice, it always pays off at the end of the day. An inventory software solution allows your company to provide better services to its customers. And satisfied customers mean more sales which inevitably lead to higher profits.

Putting it all together

An inventory management system is must-have software for modern logistics providers, retailers, and manufacturers regardless of the size of their business. Not only does it automate the core process related to products and materials in store but it also helps companies serve their customers better and stand out of the competition.

On top of that, some features of inventory software may be powered by such disruptive technology as machine learning. So if you are ready to embrace the future, an inventory management system might become your first step towards rethinking the way your business works.

Looking for skillful programmers to design an inventory database solution for your business?

Book a complimentary consultation with our tech expert.

One Response

Informative post! It clarifies the importance of inventory management systems, offering practical guidance for improving business operations effectively.