ERP management system LEO

Highly functional construction management system development for a manufacturer of concrete material.

About Nelson Precast

The Client came to us with a website and numerous productivity challenges that required a reliable custom business management tool.

For more than 10 years, Nelson Precast has been trying different ready-made solutions and even initiating custom software development. Unfortunately, all their attempts to build software have failed.

So when the Client contacted us, he had software in mind, but his idea still needed to be shaped. He provided us with many documents describing his business processes and workflow in detail, and our cooperation began. We needed to analyse all that information and, on its basis, formulate all requirements.

Expertise

Scope

Discovery phase

Product development

Maintenance

Quality Assurance

Vertical

Retail

Key results

- Job management

- Delivery tracking

See what Altamira can do for you

01

The Challenge

The main tasks Che client put on the future software were:

- To reduce the workload on employees

- To automate the estimation process

- To measure actual labour and materials

- To make scheduling and quality assurance easier

02

The Solution

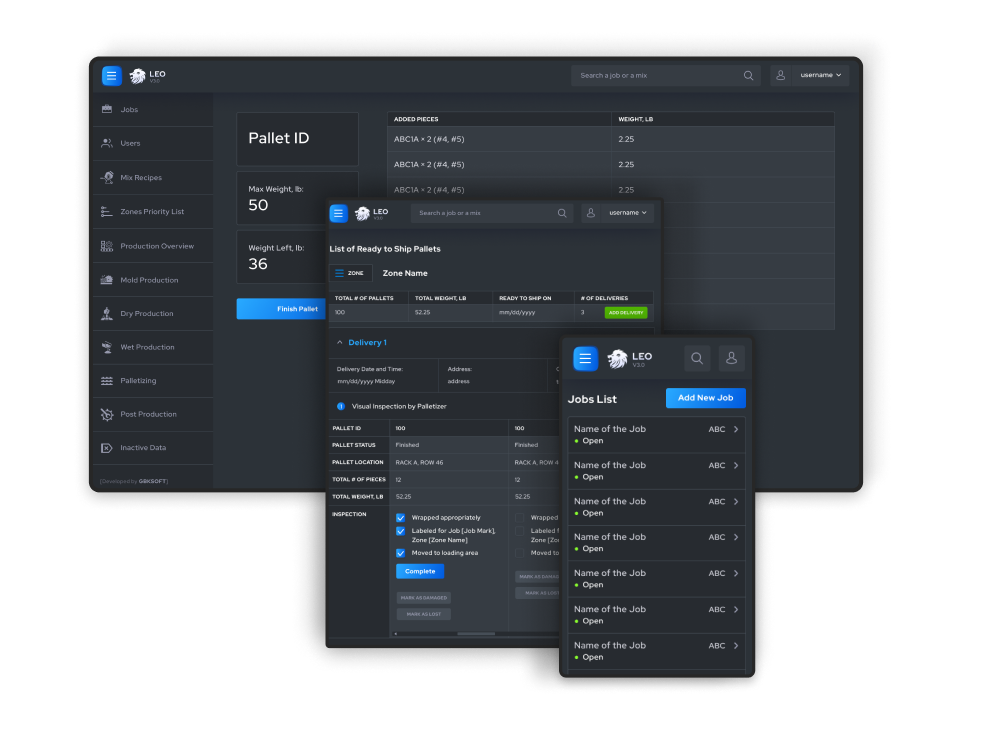

Considering all these tasks and the client’s business needs, we have written detailed specifications and began developing a construction management system called LEO.

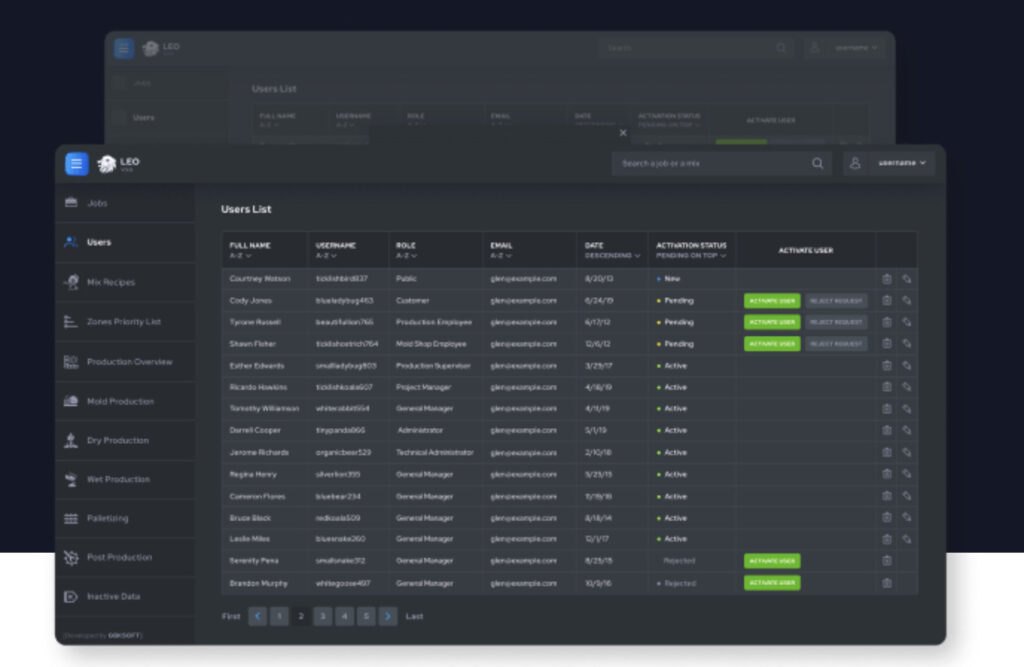

User Profiles

Nelson Precast produces custom specialty precast installations and pieces for repairing damaged originals. So many people are involved in the process, and they should have access to the LEO system on different levels. New users who create profiles need to be activated to use certain system features. There is also an option to see users in the list, sort them out, edit their profiles, or delete them.

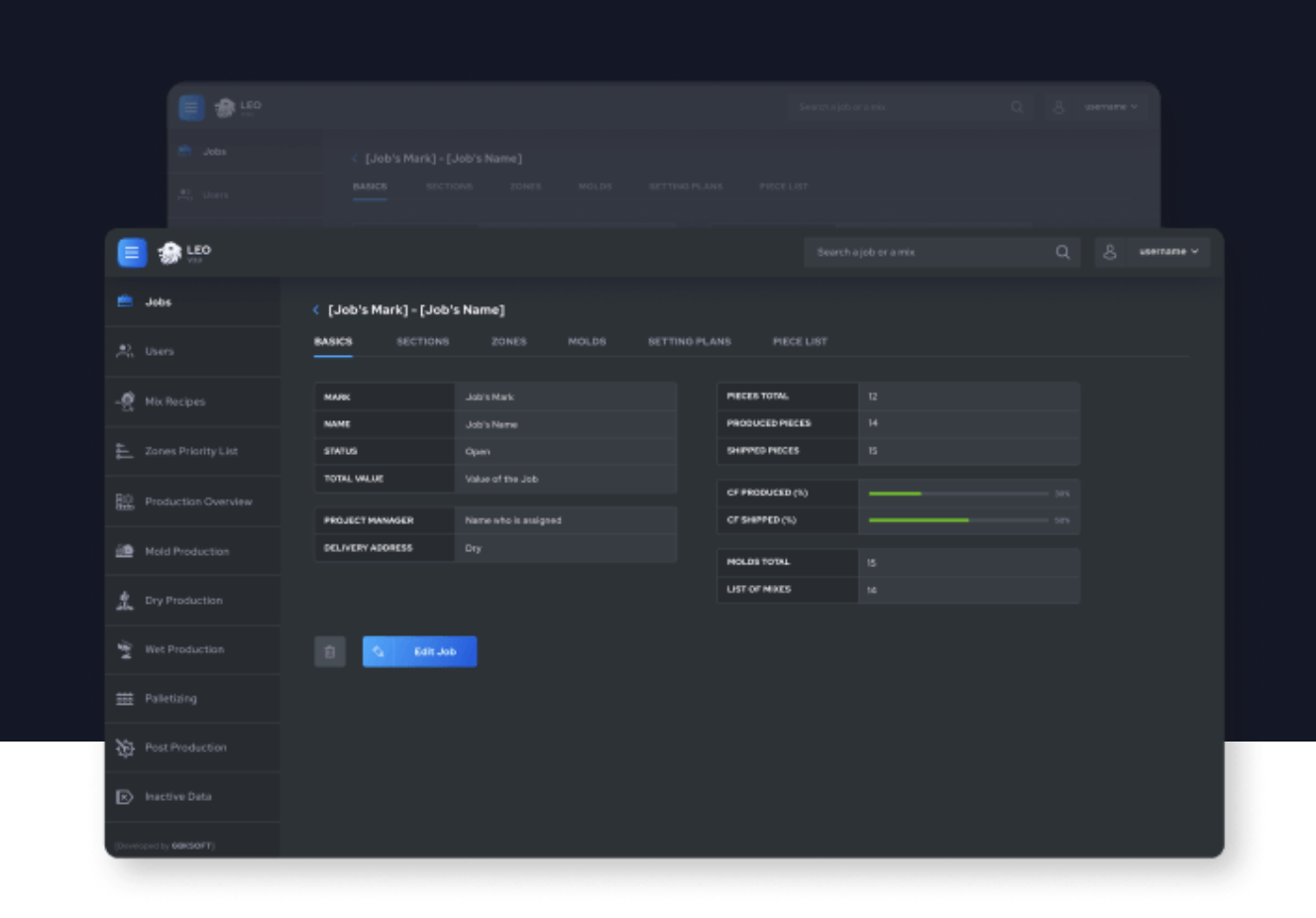

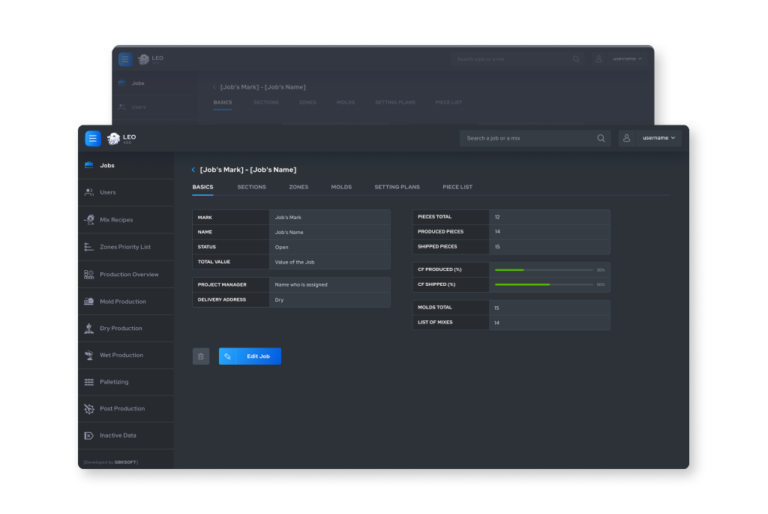

Job Management

Users of the LEO system (depending on their roles) should create, assign, and manage various job projects. We wanted to make job management clear and organised. Therefore, we added job lists where users can check the job name, status, mark, the person who manages it, and total value. All jobs can be easily filtered, edited, or deleted.

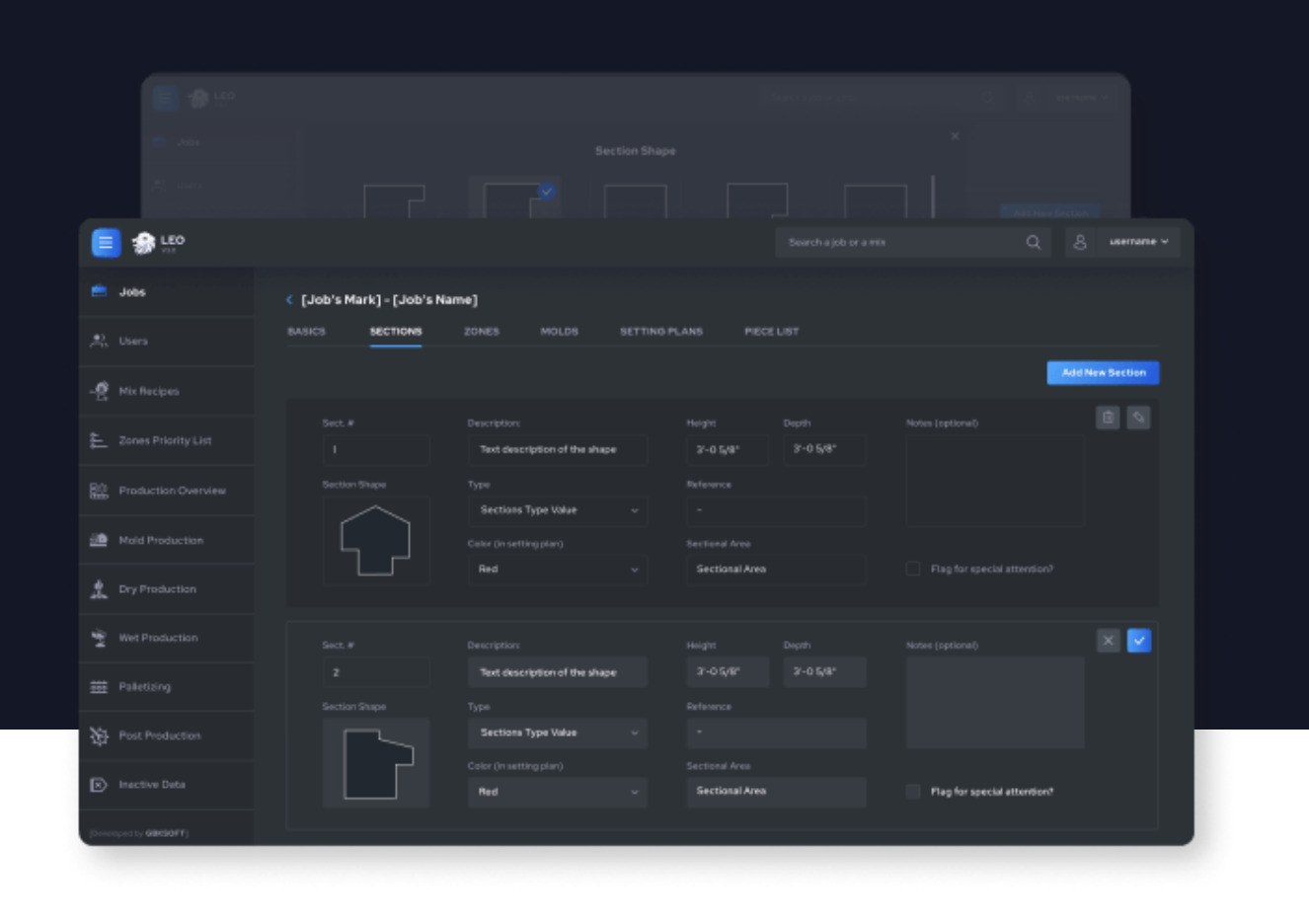

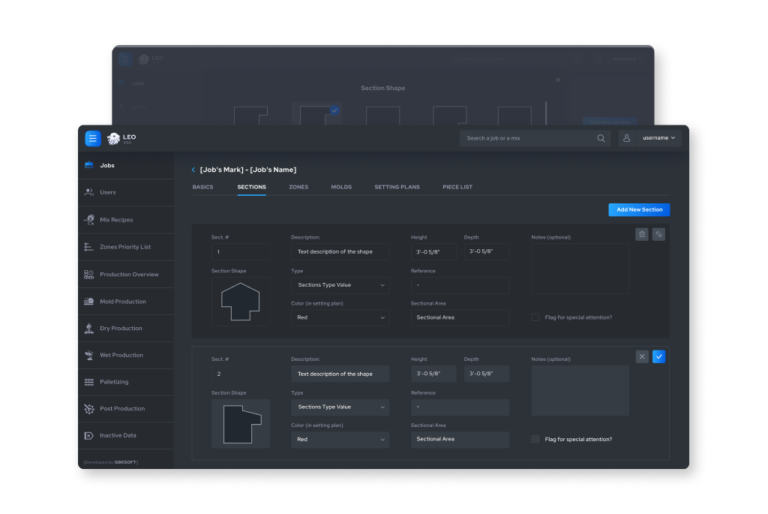

Add a Section

Since many constructions and pieces produced by Nelson Precast are custom, there was a need for an option to add a description of specific sections to job projects. A user can choose the section of necessary shape from the list and specify its type, height, depth, colour, and even an area where that section will belong.

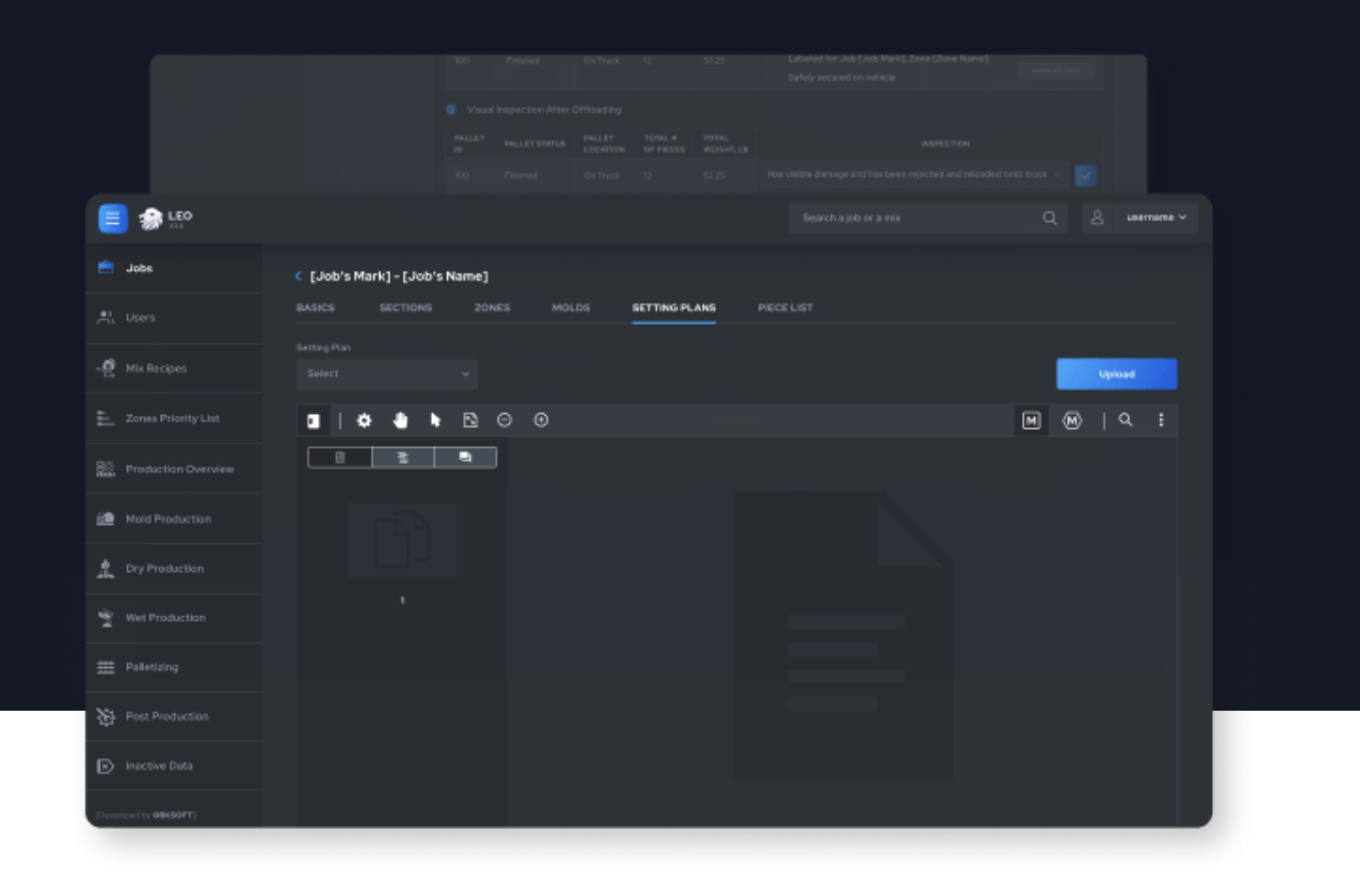

Setting Plan

LEO users can create a set plan and upload drawings easily, thanks to the PDF editor that we implemented. It is also possible to change the uploaded drawing set and create desired pieces by inserting necessary parameters (such as section, length, shape, etc.) before setting a plan. All pieces are organised in the list by their key parameters and can be easily found by LEO users.

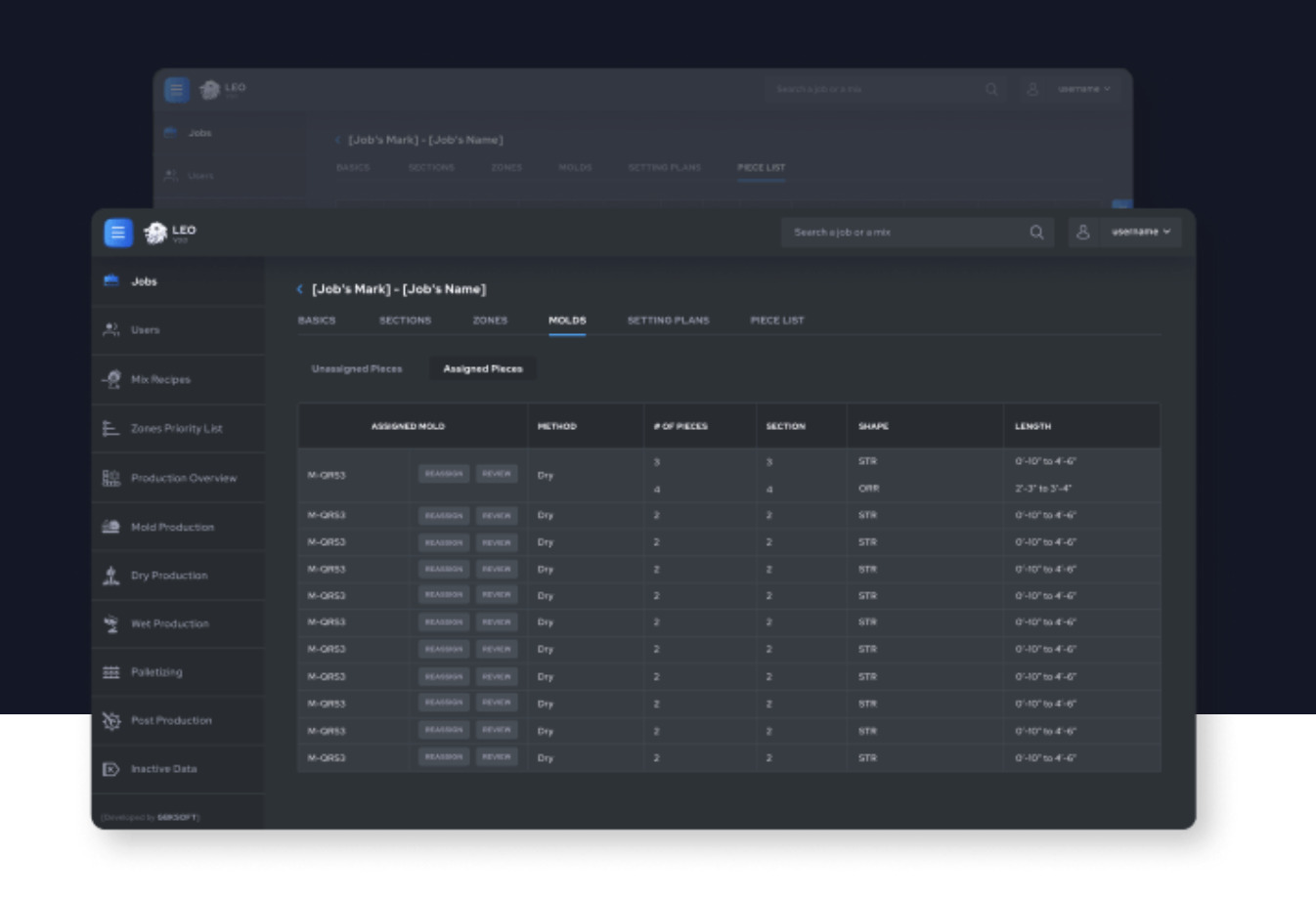

Mold Lists

A mold list is created for each job in the LEO system. The mold can be selected from a database or added as a new one. Each mold is defined by the type of piece that can be produced, and in the mould list, a user can see information about sections, the number of pieces, what moulds were assigned, and their shape and length. This section of the LEO helps manage mould assignments, review previous moulds, and reuse them for new jobs.

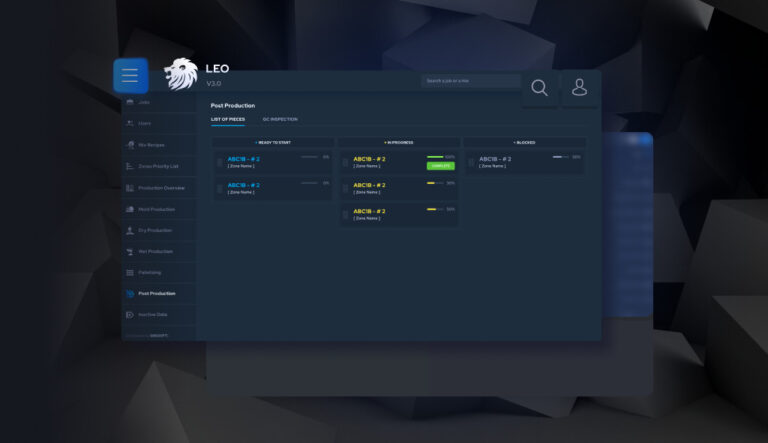

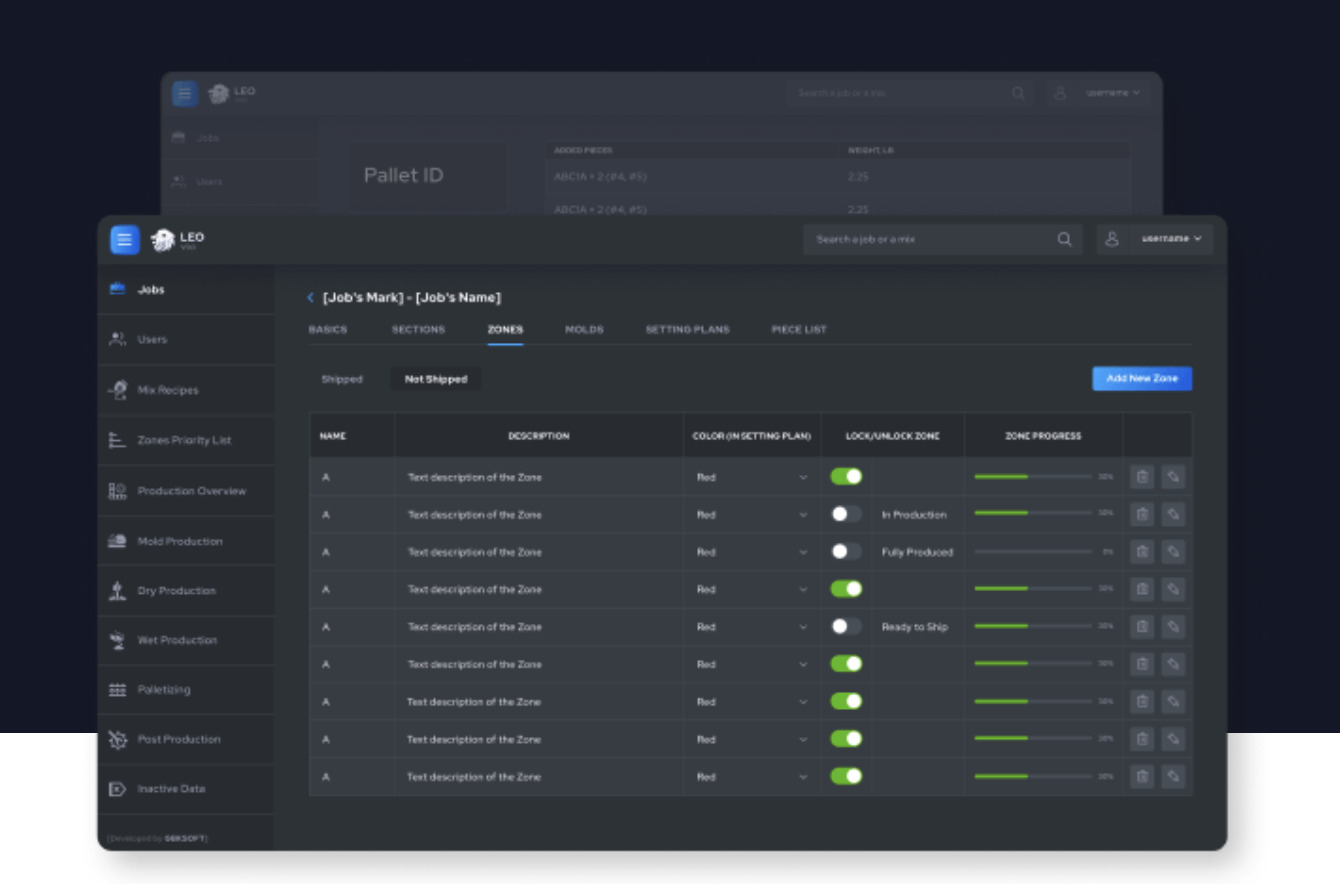

Zones Management

LEO system has a feature that lets users create lists of zones where they can specify zone description, colour, shipment details, number of pieces, weight, and required date. This enables the team to prioritise and manage zones and track production progress.

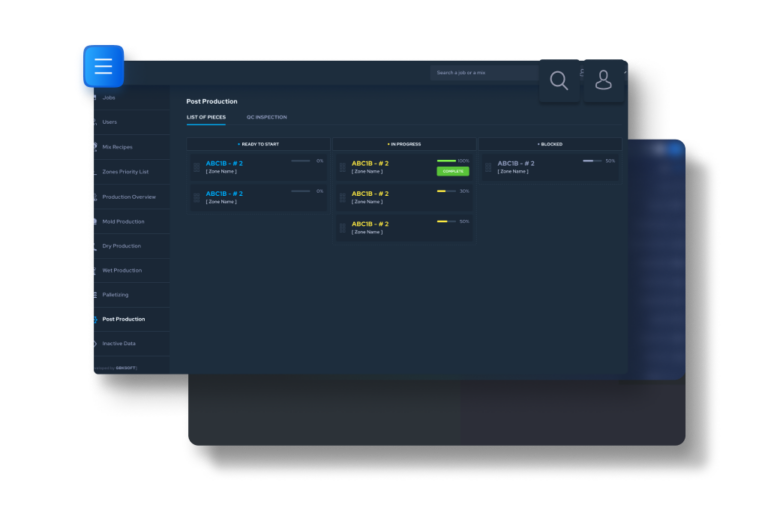

Barcodes Scanning

The LEO system users needed to be able to generate and print special barcodes for further scanning, logging their work time in the system, and tracking it. This feature also lets users scan barcodes on the label of the piece, log them as completed, and automatically update the date and time, and zone progress in the system. The barcodes for pieces and users are generated separately, allowing employees to track stone production easily.

Strive for excellence with Altamira

Join our community of successful customers, whom we helped to build and grow their businesses.

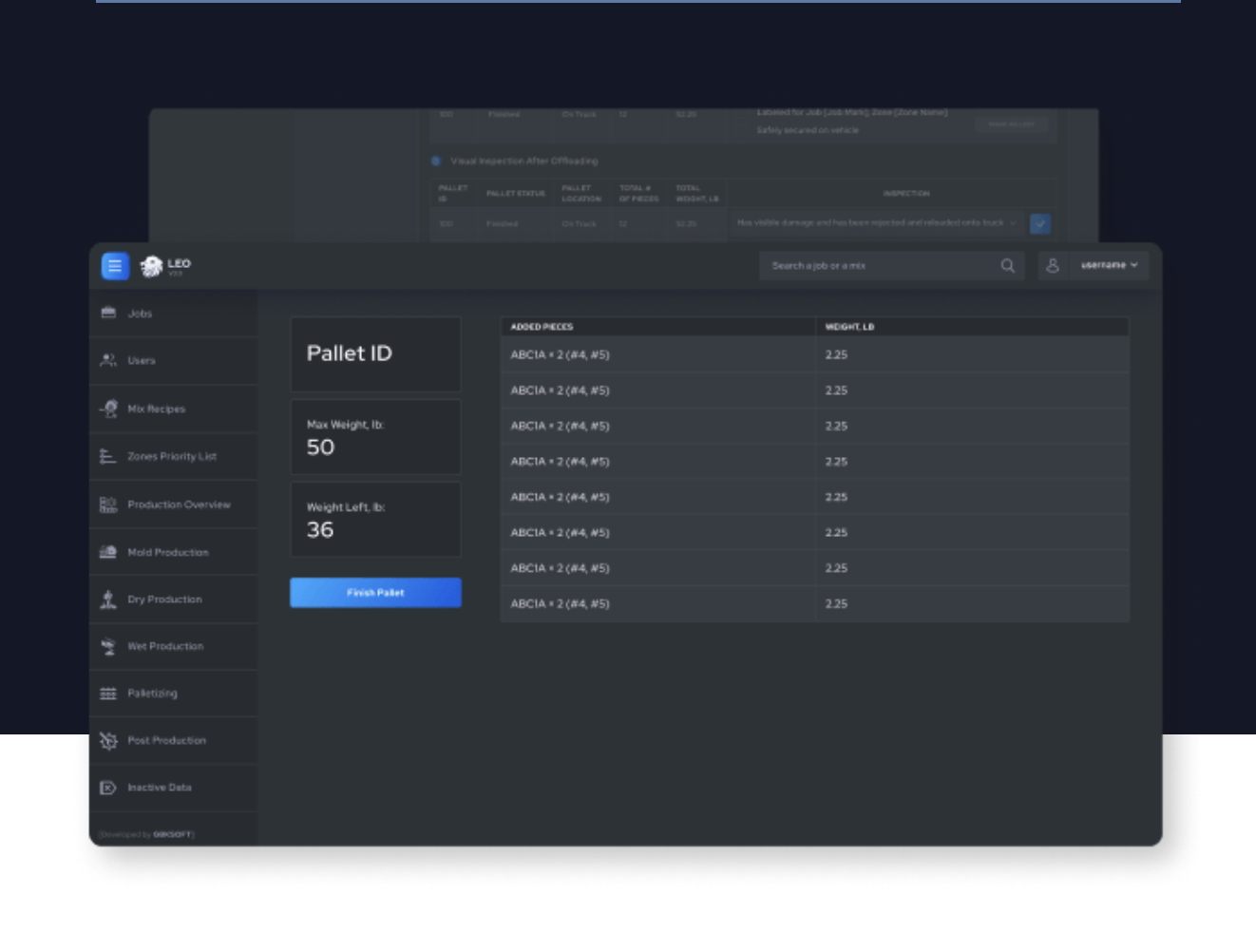

Design

When it comes to business management systems like LEO, it is essential to wrap high-quality code in a great design.

Every window, section, and button should be well thought out. Our main task was to find the right colour scheme and make all crucial parts of the LEO visible and readable.

We selected a dark grey colour as the main one. It was not too dark, so all information located within the system was easy to read. We also picked blue as a complementary colour, so LEO’s logo and all main buttons are of blue shade. It is associated with construction materials like steel or stones.

As to the secondary colours – they are pretty standard and universal. We used green, orange, and red for internal notifications and statuses requiring user attention and certain actions. Green colour to identify completed operations, orange and red to attract users’ attention to a certain item or operation.

03

The Result

Features

- PDF editor

- Advanced search

- Project planning

- Production overview

- Job management

- Quality assurance checklists

- Delivery tracking

There are less than 100 companies in the country that do anything even close to what we do. And that was that's been a big problem for us because we've had a very hard time finding business software that actually understands the logic of our very niche business.

Everything we’ve tried in the past as off-the-shelf and was unable to adapt to our workflow and didn’t have a great interface, so we brought on Altamira to create a solution specifically for our operation. The product is beautiful, seamless, quick, and responsive. Everyone I showed the product to was completely blown away. I’ve thought about the impact that this would have on our business for nearly a decade, and when my team finally saw it, they recognized how much easier it will make our jobs. It’s going to free us up to move away from data entry and enables us to do more productive work.

Throughout the specification process, they asked excellent questions. They saw potential issues and contingencies, and they took that rough document and refined that to create a more complete workflow.

Some of the ideas I had were off the wall, but they went with it. They took on some unusual challenges and they created a solution that no one has made before.Martin Sherman Marks, Chief of Operations and Finance